Complete 1600cc VW Engine Rebuild Guide

I pulled Jenny's 1600cc Type 1 engine and gave it a complete overhaul. Here's everything I learned, the tools I needed, every part I replaced, and the mistakes that cost me time and money.

Why I Decided to Pull the Engine

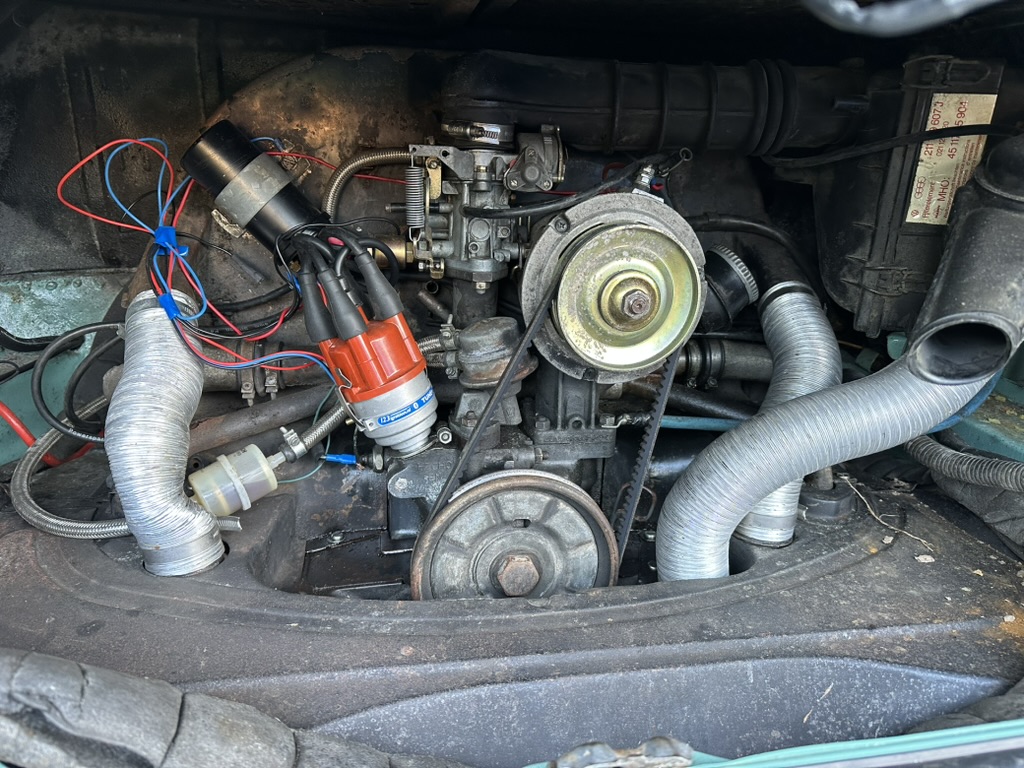

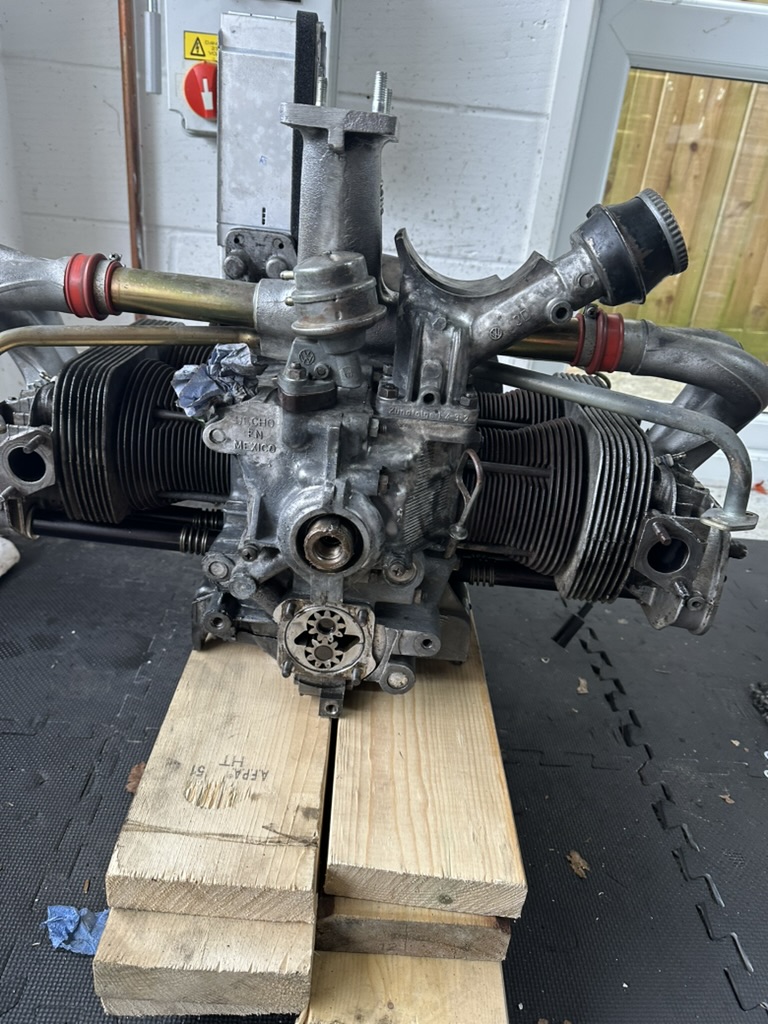

This was Jenny's engine when I finally admitted defeat—rusty, oily, and leaking from what seemed like everywhere. The main culprit? A completely corroded oil cooler seal. But that was just the visible problem.

I'd been putting this off for months, maybe even a year. The engine ran, sort of. But the oil leaks were getting worse, and I knew that ignoring it would only lead to bigger, more expensive problems down the line. It was time.

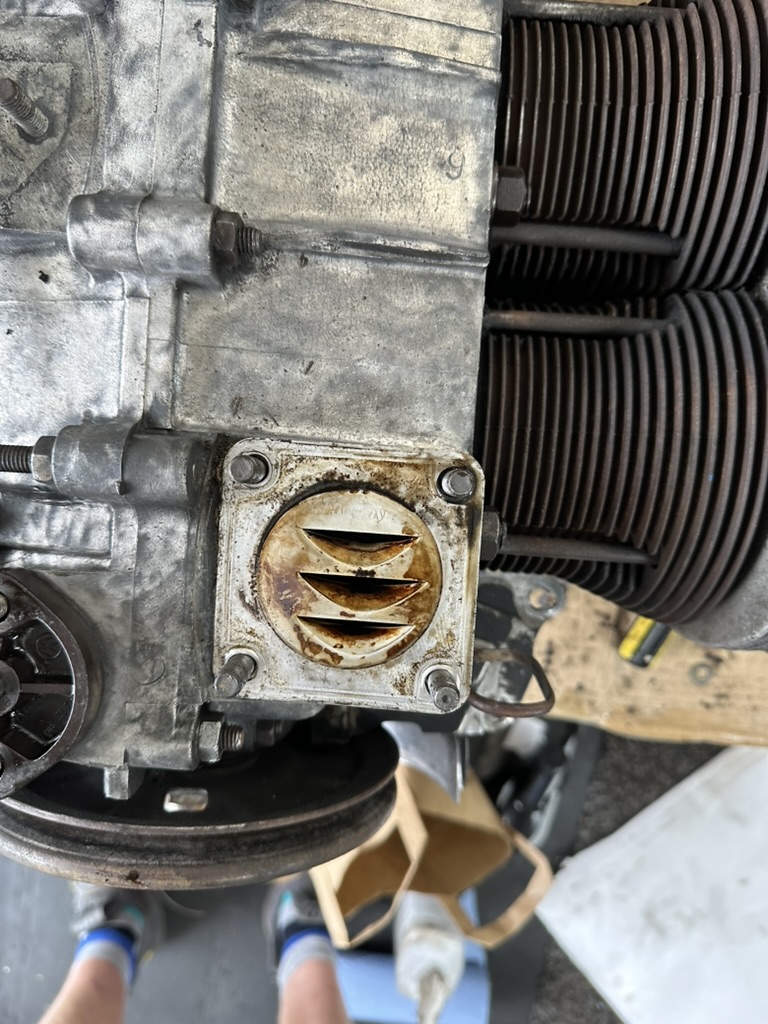

The main issue: Corroded oil cooler seal causing major oil leaks. But once I got into it, I found plenty more that needed attention—rusty tinware, worn seals, and general neglect from decades of use.

The oil cooler seal—completely gone. This was the main source of the leaks.

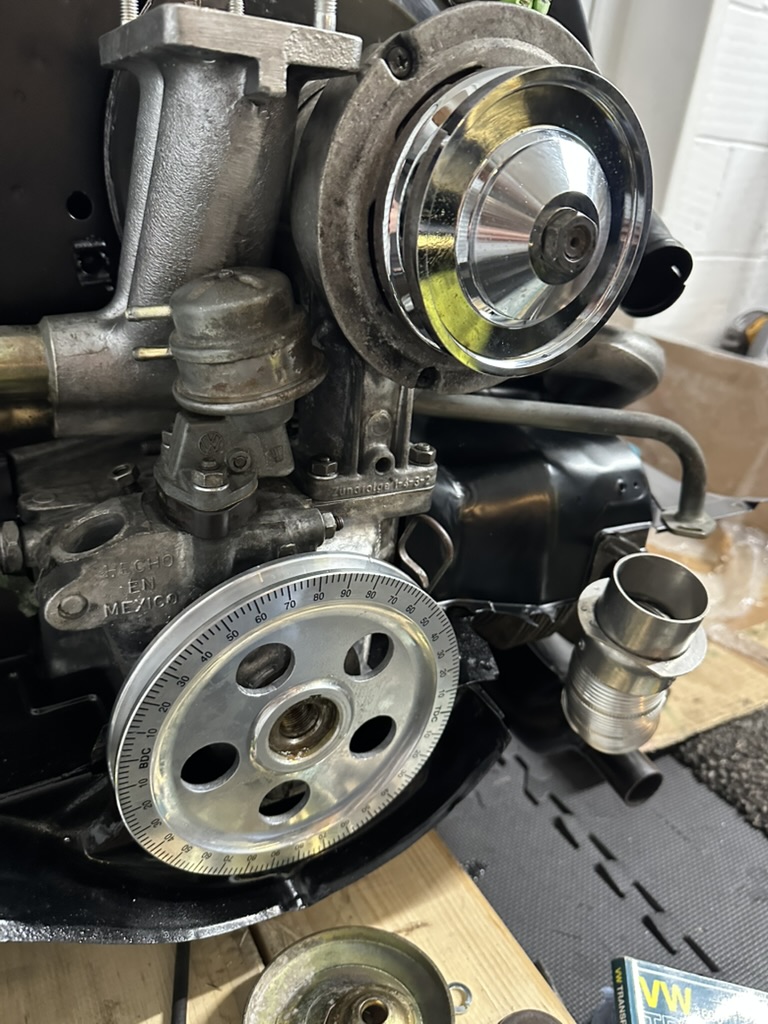

Upgrades I Made Before Starting

Before pulling the engine, I'd already upgraded to a 123 Ignition Distributor and new coil. This electronic distributor is a massive improvement over the old points-based system—no more adjusting points, better starting, smoother running.

123 Ignition Distributor fitted—one of the best upgrades I made.

If you're doing an engine rebuild, this is the perfect time to upgrade to electronic ignition. Once everything's apart anyway, it's much easier to fit.

Tools You Actually Need

I won't list every basic tool. But these made the difference between frustration and success:

🔧 Essential Tools

- Metric Socket Set (8mm-19mm) - Get quality. View on Amazon UK →

- Torque Wrench (10-150 Nm) - Non-negotiable. View on Amazon UK →

- Engine Hoist - Makes it 10x easier. View on Amazon UK →

- Wire Brush Set - For cleaning everything. View on Amazon UK →

- Feeler Gauges - £5 well spent. View on Amazon UK →

Affiliate links - I earn from purchases at no extra cost to you.

Step 1: Removing All the Tinware

Before you can drop the engine, you need to strip off all the external components. And trust me—there's more tinware on these engines than you think.

Starting to remove all the rusty old tinware—it all has to come off.

The Rusty Reality

My tinware was in rough shape. The heat risers were completely rusted through—barely holding together. This is common on Bay Windows, especially if they've spent years outside or in damp storage.

Old split heat risers—completely rusted through. These had to go.

Step 2: Label EVERYTHING

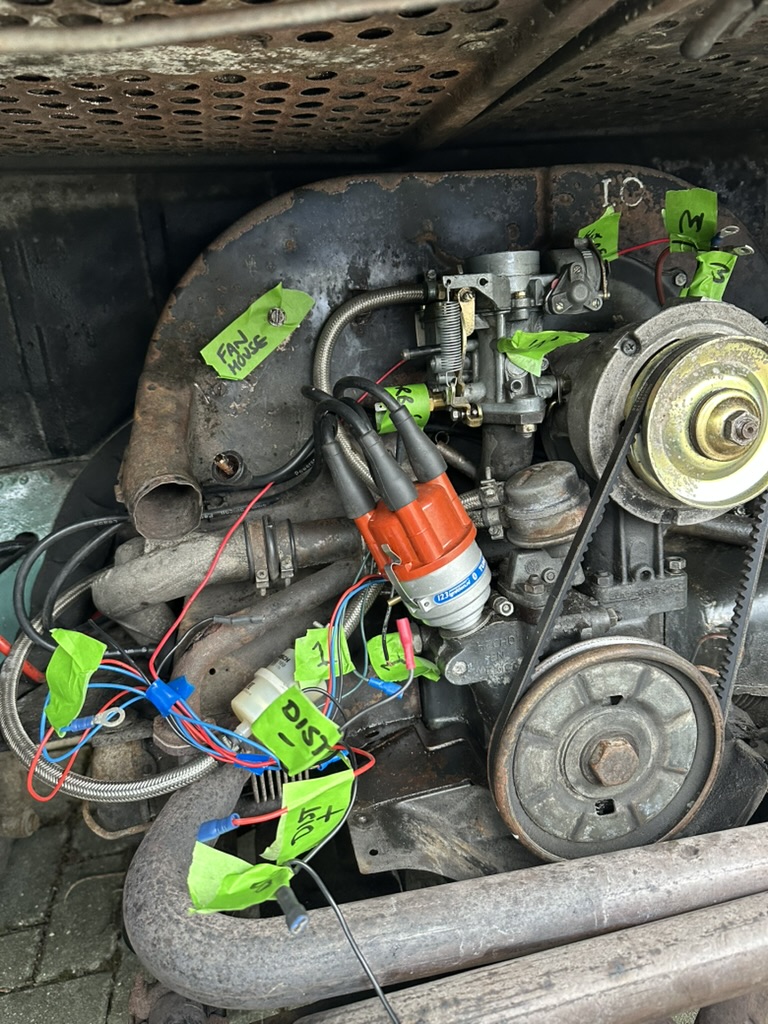

This is the single most important piece of advice I can give you: label everything before you disconnect it.

Meticulously labelling everything. You'll thank yourself during reassembly.

I used masking tape and a marker → to label every single wire, hose, and connection. Where does it go? What does it connect to? Write it down. Take photos. Be obsessive about this.

Trust me—three weeks from now when you're trying to remember which wire goes where, you'll be incredibly grateful for the 20 minutes you spent labelling everything.

Step 3: Dropping the Engine

Here's the beautiful simplicity of air-cooled VW engines: four bolts. That's it. Four bolts connect the engine to the gearbox.

Dropping the engine—just four bolts to undo!

Before You Drop It:

- Disconnect battery (obviously)

- Drain oil (have a container → ready)

- Disconnect throttle cable

- Disconnect accelerator cable

- Remove fuel line (it will drip—have rags ready)

- Disconnect all electrical connections

- Remove exhaust (four nuts at heat exchangers)

Label Every Fastener

As you remove bolts, nuts, and washers, put each set in its own labelled bag. I'm serious about this—label EVERYTHING.

Every nut, bolt, and washer in its own labelled bag. This saved me hours during reassembly.

Getting It Out

Support the engine with a jack (I used a trolley jack → with a block of wood). Remove the four engine-to-gearbox bolts. Then carefully slide the engine straight back—it needs to come off the gearbox input shaft cleanly.

Have a friend help you guide it. Engines aren't heavy (about 60kg), but they're awkward, and you don't want to damage anything.

Getting the engine out from under the van—awkward but doable with two people.

TAKE PHOTOS

Before you remove anything else, take photos. Every angle. Every connection. You cannot have too many photos.

Take photos of everything before you remove it. You'll need these later!

Step 4: Stripping It Down

Now the engine's out, it's time to strip everything off. This is where you really see what you're working with.

Tinware, fan housing, carb, alternator, and pulley all removed.

Off came: tinware, fan housing, carburetor (which I was replacing anyway), alternator, pulley, and all the cooling shrouds. Every piece got inspected as it came off.

Piles of rusty, oily tinware—decades of neglect evident.

The tinware was in shocking condition. Years of heat, oil, and moisture had taken their toll. Some pieces would be salvageable with work. Others needed replacing.

Step 5: Getting Back to the Block

With everything external removed, I finally got back to the block itself—or close to it.

Back to the block—or thereabouts. Now the real work begins.

Step 6: Cleaning Everything

This took longer than I expected. Every surface needs to be absolutely spotless before reassembly.

Wire brush and brake cleaner became my best friends. So. Much. Cleaning.

I went through cans of brake cleaner →. Wire brushed every surface. Scraped off decades of oil, dirt, and grime. It's tedious work, but it's essential. Any dirt left behind could cause problems later.

Step 7: Clutch and Rear Main Seal

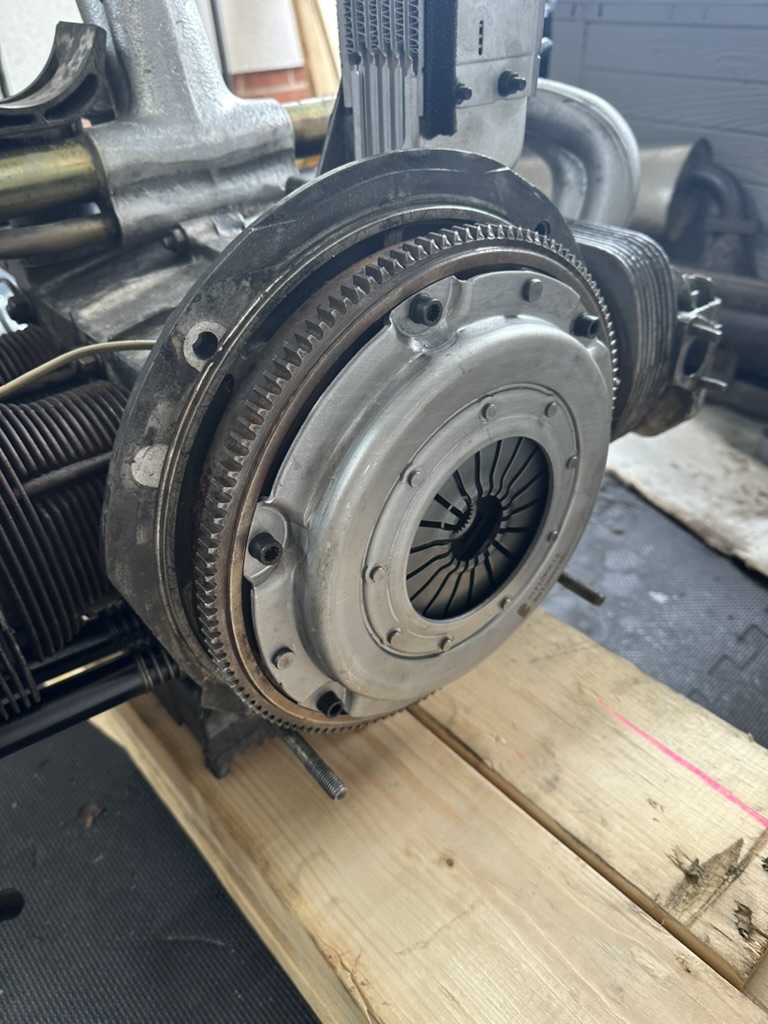

With the engine out, I could finally access the clutch and rear main seal—both of which needed attention.

Clutch removed. The rear main seal was quite the mess!

The rear main seal → was leaking—no surprise there. This is a common issue on older VW engines, and it's impossible to replace with the engine in the van. So while everything's out, it's the perfect time to sort it.

Push Rod Tubes

I also removed the old push rod tubes →. These were oil-soaked and past their best. More importantly, I labelled each push rod in order—they need to go back in the same positions they came out of.

Removing old push rod tubes and labelling the push rods in order—critical for reassembly.

Step 8: More Cleaning

Did I mention cleaning? Because there's a lot of it. Every surface that will mate with a gasket needs to be spotless.

More brake cleaner, more cleaning. I probably went through 6-7 cans of the stuff.

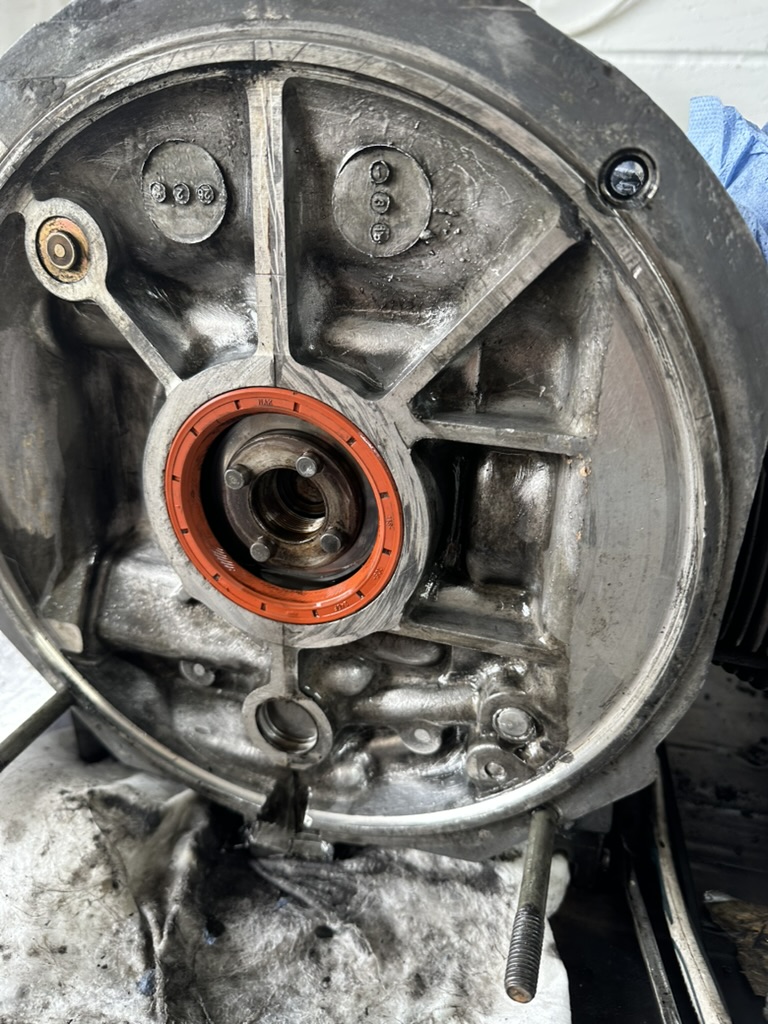

Step 9: New Rear Main Seal

With everything clean, I fitted the new rear main seal. The difference is night and day.

New rear main seal fitted. Everything's nice and clean now too.

This seal is what stops oil from leaking out the back of the engine. Get it right now, and you won't have oil dripping onto your clutch later.

Complete Rebuild Kit:

- Full Gasket Set - Replace every gasket. View on Amazon UK →

- Piston & Cylinder Kit - 1600cc standard bore. View on Amazon UK →

- CSP Push Rod Tubes (Spring-Loaded) - Spring-loaded design prevents leaks. View on eBay UK →

- Rear Main Oil Seal - Critical seal. View on Amazon UK →

Upgrades I Made:

- 123 Ignition Distributor (Bluetooth) - Game changer. Electronic ignition, no more points. View on eBay UK →

- Vintage Speed Exhaust - Better flow, classic sound. View on eBay UK →

- Weber Progressive Carburetor - Massive improvement. View on Amazon UK → | Full guide →

- Upgraded Oil Cooler - Better cooling. View on Amazon UK →

Step 10: Restoring Original Parts

I wanted to keep as many original parts as possible—especially the heat exchangers. They were rusty but solid, so I decided to restore them rather than replace them.

After extensive wire brushing, priming the original heat exchangers.

Hours of wire brushing removed the worst of the rust. Then I primed them with high-temperature primer →, ready for paint.

Spraying the heat exchangers—no need for perfection here, they'll get hot and discolour anyway.

I used high-temperature paint in black →. These will get incredibly hot, so you need proper heat-resistant paint. And don't worry too much about perfection—they're going to discolour with heat anyway.

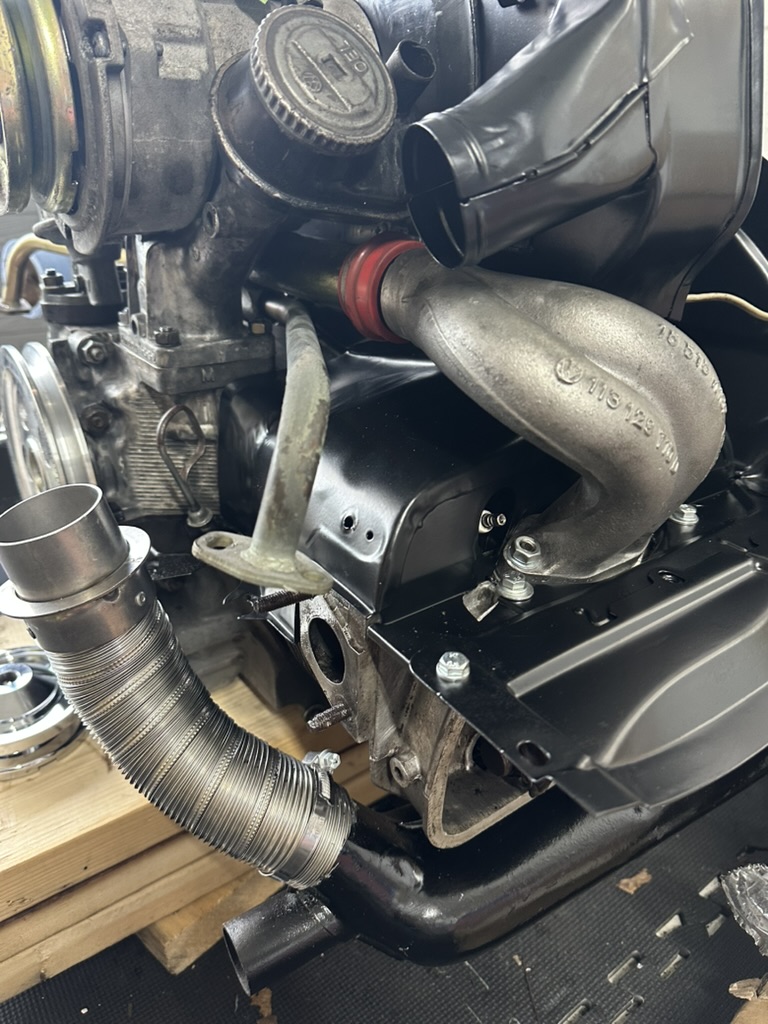

Step 11: New Inlet Manifolds and Heat Risers

The old heat risers were rusted through, so I bought new ones →. Same with the inlet manifolds →—fresh parts for a reliable setup.

New heat risers and inlet manifolds going on—much better than the rusty old ones.

Step 12: New Clutch

With the engine out, fitting a new clutch is straightforward. It would be criminal not to do this while everything's accessible.

New clutch fitted—smooth operation for years to come.

Step 13: New Oil Cooler

Remember that corroded oil cooler seal from the beginning? New oil cooler →, new seals, no more leaks.

New oil cooler fitted—this was the main reason for pulling the engine in the first place.

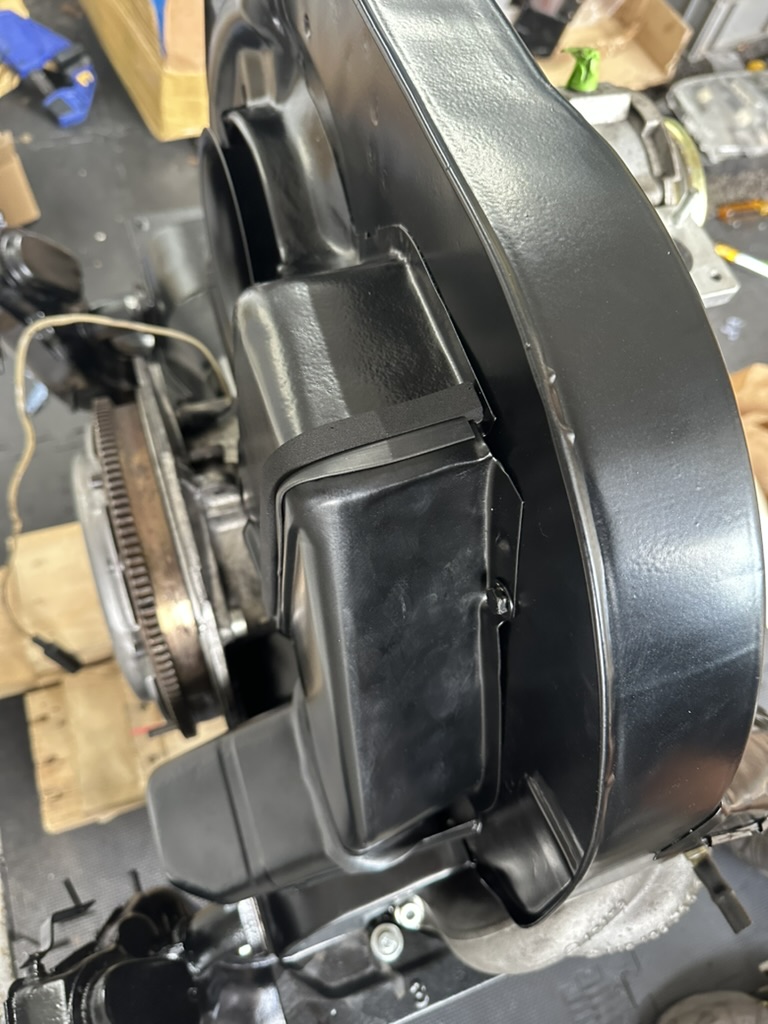

Step 14: Reassembling with Restored Parts

Now the restored heat exchangers go back on, along with the original fan housing and oil cooler cover—all shot blasted and resprayed.

Resprayed 'original' heat exchangers going back on. They look fantastic.

Original fan housing and oil cooler cover—shot blasted and sprayed. Now back on and looking brilliant.

Step 15: Alternator and New Pulley

The original alternator was working fine, so I kept it. But I upgraded to a new aluminium pulley—lighter and looks better too.

Original alternator with new aluminium pulley fitted.

Step 16: CSP Stainless Steel Heater Hoses

One upgrade I'm really happy with: CSP stainless steel heater hoses. They look fantastic and will never rust like the old steel ones.

Stainless steel CSP heater hoses fitted—these look brilliant and will last forever.

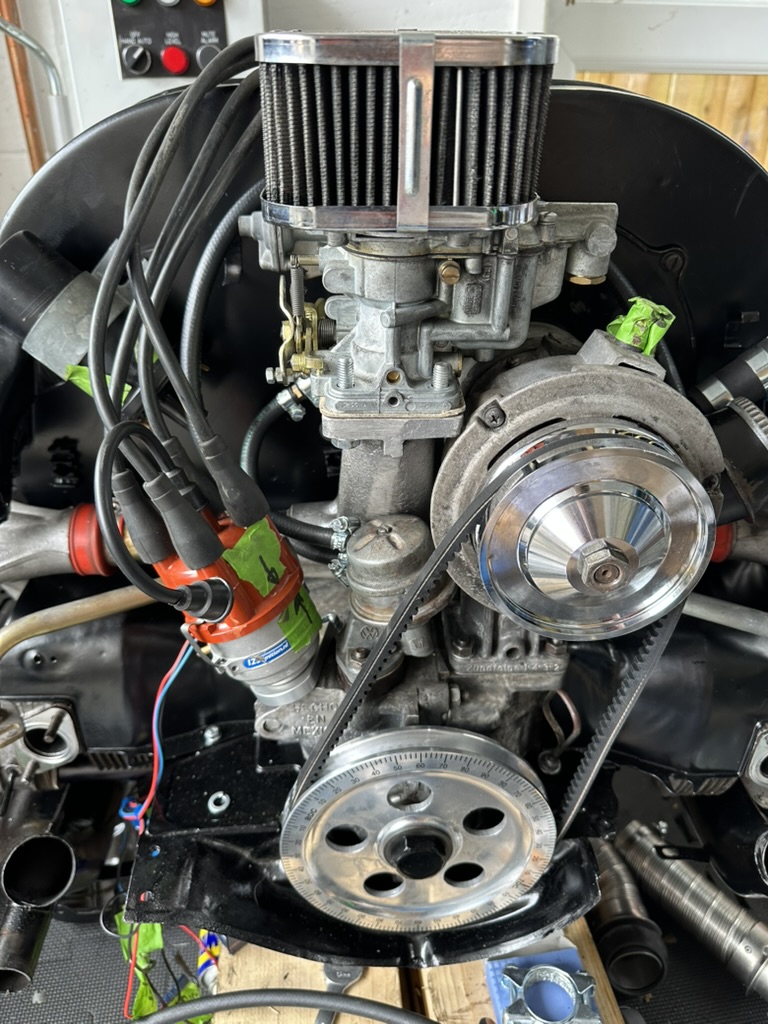

Step 17: Weber Carb and Distributor

The crowning glory: new Weber Progressive carb → and the 123 Ignition Distributor all fitted and ready to go.

New Weber Progressive carb and distributor fitted. This transformed how Jenny runs.

The Weber Progressive 32/36 DGEV is such a massive improvement over the stock Solex carb. Better throttle response, easier starting, more reliable. Combined with the electronic ignition, the engine runs better than it probably ever has.

I wrote a complete guide on installing and tuning the Weber carb here: Weber Progressive Carb Installation Guide →

Step 18: New Push Rod Tubes

The old push rod tubes were oil-soaked and past saving. New ones went on, and for the first time in probably 40 years, this engine is oil-free.

New push rod tubes and now completely oil-free. What a difference.

Step 19: Back In and Ready to Go

Finally, after weeks of work, the engine went back in. The reverse of removal—support it on the jack, line it up carefully with the gearbox input shaft, slide it forward, bolt it up.

Engine back in and ready to go. Clean, sealed, upgraded, and reliable.

Reconnect everything (this is where those labels and photos save you), fill with oil, connect the battery, and cross your fingers.

First Start

This is the moment. Weeks of work come down to turning the key.

Jenny fired up immediately. The sound of a clean, properly sealed engine is genuinely special. No leaks, smooth idle, plenty of power. All that work was worth it.

Essential Reading

Before you start an engine rebuild, get yourself a copy of How to Keep Your Volkswagen Alive by John Muir →. It's THE essential book for any VW owner. Clear instructions, helpful illustrations, and written in plain English. Also grab the Haynes VW Transporter Workshop Manual → for technical specs and torque settings.

Mistake #1: Not Having All Parts First

Needed a seal three days in. Engine sat half-assembled waiting for delivery. Order everything upfront.

Mistake #2: Rushing Valve Adjustment

Rushed it first time. Engine ran rough. Did it properly with feeler gauges →—transformed how it ran.

Mistake #3: Using Old Hardware

Some bolts are one-time-use. Learned when one snapped. New hardware isn't expensive—engine damage is.

Supplies You'll Need

Don't underestimate how many consumables you'll go through:

- Brake Cleaner Spray (buy a 12-pack!) → - I went through 6-7 cans

- Wire Brush Set → - For all that rust removal

- Mechanics Gloves → - Keep your hands clean

- Masking Tape & Markers → - For labelling EVERYTHING

- Shop Rags → - You'll need loads

- Parts Organizer Bins → - For keeping fasteners sorted

Cost Breakdown

| Item | Cost |

| Oil cooler & seals | £120 |

| Gasket and seal kit | £85 |

| Weber carburetor | £225 |

| 123 Ignition distributor & coil | £180 |

| Clutch kit | £150 |

| CSP stainless heater hoses | £95 |

| Heat risers & inlet manifolds | £110 |

| Push rod tubes | £65 |

| Aluminium pulley | £45 |

| Shot blasting & paint supplies | £80 |

| Brake cleaner, oils, supplies | £95 |

| Total | £1,250 |

Time: About 3 weeks (evenings and weekends, not rushing).

I saved money by restoring the original heat exchangers, fan housing, and oil cooler cover rather than buying new ones. Shot blasting and respraying them cost about £80 total—new parts would have been £300+.

Was It Worth It?

Absolutely. Jenny now runs better than she probably ever has. No more oil leaks. The Weber carb and electronic ignition transformed how she drives. The confidence of knowing exactly what's been done is priceless.

More importantly, I learned an enormous amount. I understand this engine now. I know what every part does, where everything goes, how it all works together. That knowledge is worth as much as the mechanical improvements.

And honestly? There's something deeply satisfying about pulling an engine, fixing everything, and having it fire up first time. If you're considering this, do it. Take your time, label everything, take photos, and enjoy the process.

Key Takeaways

- Label everything - Cannot stress this enough

- Take endless photos - More than you think you need

- Order all parts upfront - Don't wait for deliveries mid-job

- Budget more time for cleaning - It takes way longer than expected

- Restore what you can - Original parts can often be saved

- Upgrade while it's apart - Weber carb and electronic ignition = huge improvements

- Don't rush - This isn't a race

Questions about engine rebuilds? Drop me a message on Instagram @jennythebus—happy to help!